The processing raw materials of medical equipment parts mainly include aluminum alloy, AL6061, 6063, 7075, etc., stainless steel SUS303, SUS304, SUS316, etc. The processing accuracy of medical equipment parts is high required, with the characteristics of multiple cross holes and fine threads.

Components features:

Processing technology | CNC precision machining |

Material Mode | AL7075 |

Sample/production lead time | 7/15 working days |

Product processing accuracy | min-0.01mm |

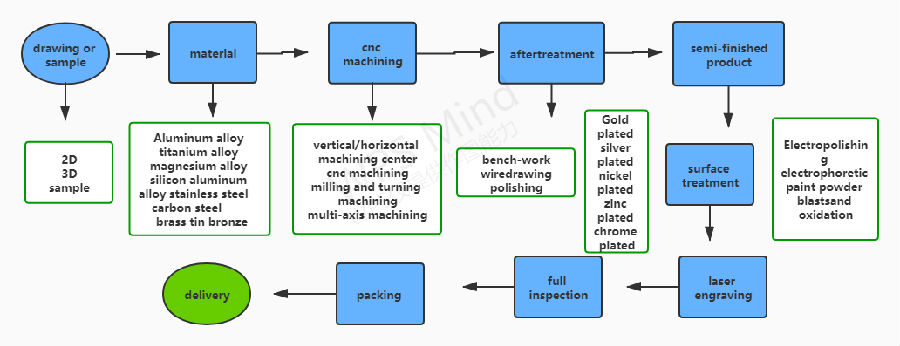

Product processing | CNC machining - full inspection - packaging - delivery |

Product standard | 18mm*78mm |

Surface treatment | wiredrawing |

Packing standard | Blister box + carton box or according to customer requirements |

Related testing equipment | Caliper, CMM, micrometer, plug rod, etc |

Flow chart of product implementation:

SWKD focus CNC precision machining for many years, the processing has a very wide range of materials, conventional processing of materials of aluminum alloy, carbon steel, copper, stainless steel. Special material are steel, iron, nickel alloy, high silicon aluminium, kovar alloy, titanium alloy, etc., products are widely used in medical equipment industry, drone industry, automation equipment, optical communication industry, etc.